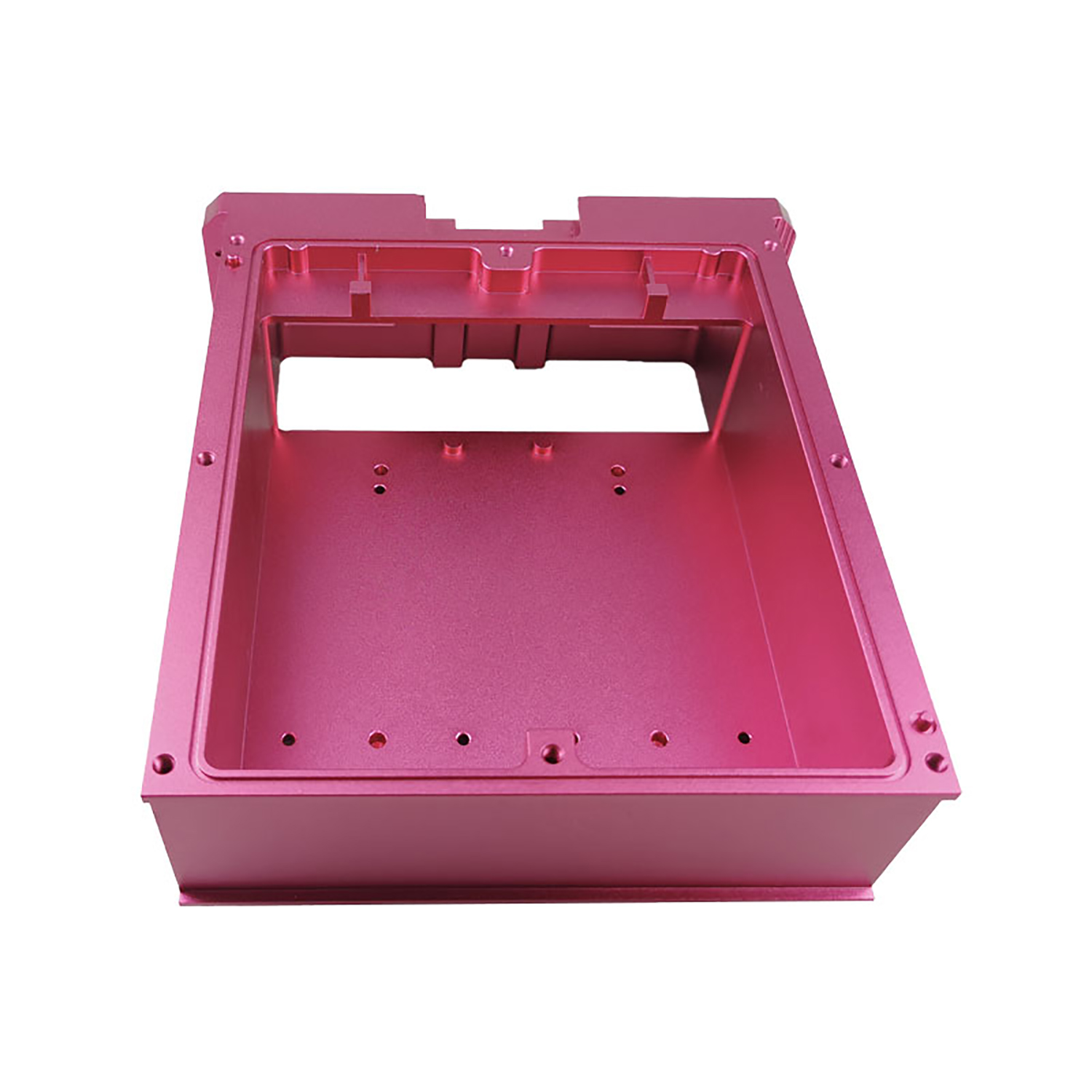

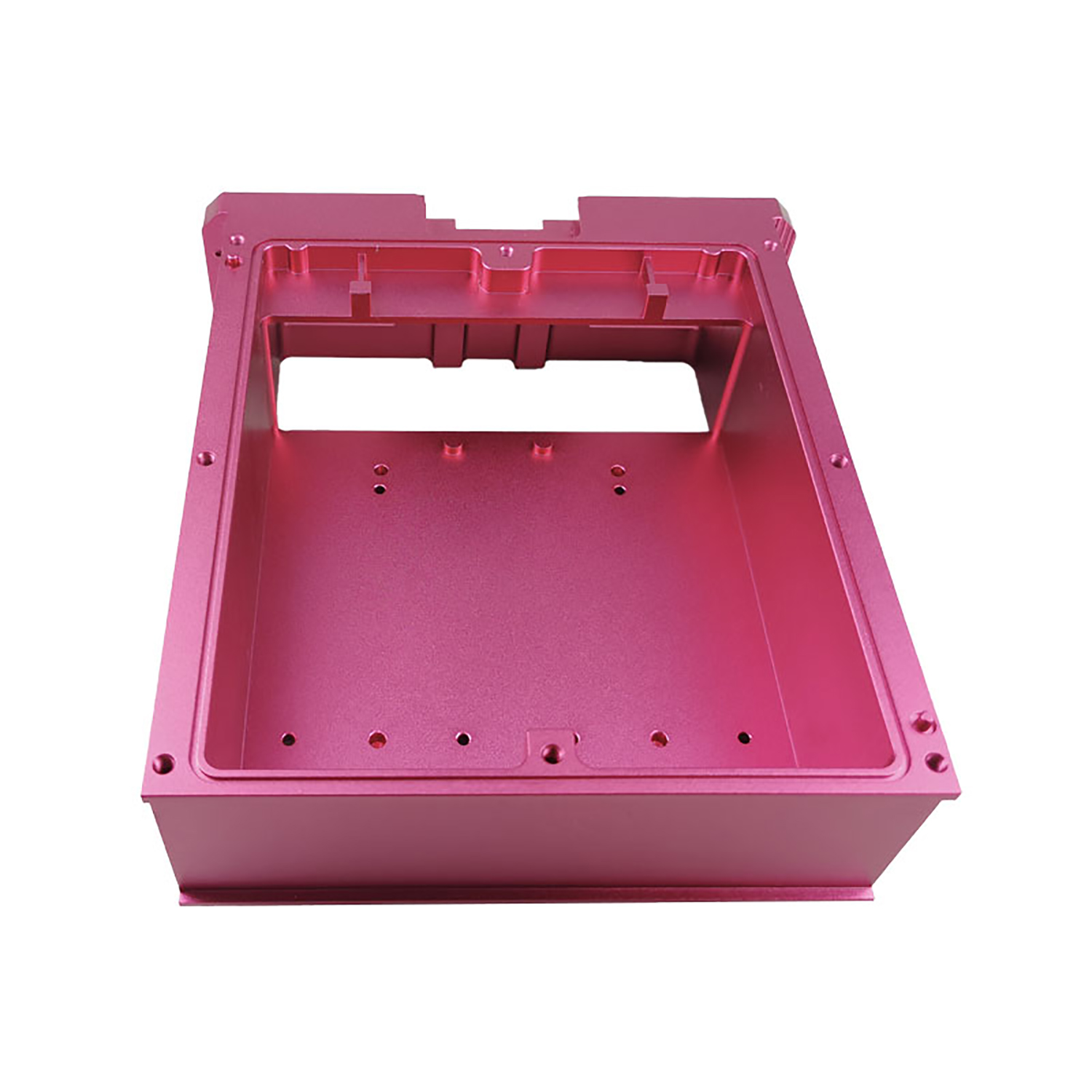

【Part name】 CNC processing microwave communication equipment 6061

aluminum alloy shell

【Manufacturing process】 Four-axis CNC milling

【Product features】 multi-faceted processing

【Material used】 Aluminum alloy 6061-T6

Aluminum alloy 6061 is a heat-strengthened alloy with good

formability, weldability, machinability , medium strength. It can

still maintain good operability after annealing.

Typical use: aerospace aluminum is used to make aircraft skins,

fuselage frames, girders, rotors, propellers, fuel tanks, siding

landing gear pillars, as well as rocket forging rings, spacecraft

siding, etc.

【Surface treatment】Red anodized

For most aluminum alloy products that require surface decoration,

after chemical electrochemical polishing, anodized with a solution,

an oxide film with high transparency can be obtained. The oxide

film can absorb dyes of many colors, red is selected. This layer of

color is both a protective film a decorative film.

【Benefits after treatment】

1. Prevent corrosion of aluminum products

2. Decorative aluminum products

3. Enhance hardness wear resistance

4. As an electrical insulating layer

5. As the bottom layer of spray paint

6. As the bottom layer of electroplating

This part belongs to the appearance of the workpiece, after surface

treatment, it is more corrosion-resistant, the appearance is more

exquisite in color.

【Processing equipment】 Four-axis CNC machining center

Processing equipment types: three-axis CNC machining center,

four-axis CNC machining center, five-axis CNC machining center,

gantry milling machining center, drilling tapping machine, CNC

lathe, precision grinder, molding press, autoclave, western

machine, fast wire cutting Machine, middle wire cutting machine,

slow wire cutting machine other processing equipment.

【Precision size】 For finishing, the key position tolerance

requirement is ±0.02mm; the size is 375mm*52mm*355mm

Precision types: finishing, ultra- precision machining , finishing,

semi-finishing, roughing, finishing, rough grinding, fine grinding,

other (as the degree of precision increases, the price will

increase)

【Quantity Delivery Time】

Sample (1 piece minimum order): 2-7 days;

Small medium batch processing: 7-20 days;

Mass production: 20-35 days

| According to your drawing(size, material, required technology, etc) |

| +/-0.001 mm - 0.01 mm (Customized avaiable) |

| Ra0.2 - Ra3.2(Customized avaiable) |

| Turning, Milling , Drilling, Auto lathe, Tapping, Surface

treatment, etc. |

| PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF |

FAQ:

1. Are you a factory or a trading company?

A: We are a factory which has been specialized in cnc machining &

automatic manufacturing for more than 30 years.

2. Where is your factory and how can I visit it?

A: Our factory is located in Shenzhen city and you can get more

detailed information by browsing our website: www.cnbenky.com

3. How long can I get some samples for checking and what about the

price?

A: Normaly samples will be done within 1-2 days (automatic

machining parts) or 3-5 day (cnc machining parts). The sample cost

depends on all information (size, material, finish, etc.). We will

return the sample cost if your order quantity is good.

4. How is the warranty of the products quality control?

A: We hold the tightend quality controlling from very begining to

the end and aim at 100% error free.

5.How to get an accurate quotation?

♦ Drawings, photos or samples of products.

♦ Detailed sizes of products.

♦ Material of products.

♦ Surface treatment of products.

♦ Ordinary purchasing quantity.